Our Clients

The following Case Studies are based on real customers, real problems and real solutions. By their nature the issues and problems are company confidential so we have chosen to make them anonymous. If you want to contact any of these customers or discuss them, then please get in touch using the form below.

Case Studies

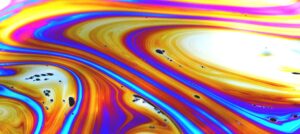

Reducing the variation in a production process to improve customer satisfaction and minimise scrap

Situation Our client’s international business produces colour coated films used in product packaging and presentation applications. Consistency in the film colour produced is a critical

Creating A Lean Chemical Recovery Process

Situation The client company manufactures specialist additives for chemical coating of metal surfaces. The original process created significant amounts of waste in the form of

Creating A Lean Furnace Process

Situation The client company manufactures specialist industrial heating equipment and associated materials. One of their processes is a continuous furnace feed through which sub-assemblies must

Value Stream Mapping (VSM) and improvement of an absence management process

Situation Our client is a large organisation with a complex structure and operates across many separated locations. Groups within some of the larger sites had

How to Improve the Quality of an Assembly Process in High Volume Consumer Products.

Situation We were introduced to a manufacturer of sub-assemblies for high-volume consumer products that was experiencing process yields that were lower than goal. Sub-assemblies were

Transforming the process for obtaining Contractor Access into a High Security Site.

Situation A major construction project commissioned by the UK Government requires the highest levels of security access. However, there are in excess of 200 contractors

Change from 100% End-Of-Line Inspection to Inline Controls with Higher Customer Quality

Situation The client manufactures precision plastic parts for prestigious automotive customers who have extremely high quality standards. On one particular product line, the client had

Value Stream Mapping (VSM) and improvement of a vehicle hire process

Situation Our client is a construction business specialising in roads and other civil engineering activities. We were asked to work with a department who provide

Our Clients

- Rockwell Solutions

- Standard Life

- Scottish Enterprise

- Highland Spring

- North British Distillers

- Argenta Global

- North Ayrshire Council

- Prudential

- Highland Council

- Babcock International

- Scottish Power

- Inverness Hospice

- Edinburgh Airport

- Jabil

- Harbro

- Sartorius Stedim

- Wood Group

- Cabinet Office UK

- John Dewar & Sons

- Novar

- SPH Housing

- North West Employers

- Student Loans Company

- C.M.P.S.

- The Edrington Group

- Ministry of Defence

- Aker

- Santander

- The Work Foundation

- Bespak

- Gent, Honeywell

- Brand Rex

- New Medical Technology

- Harper Collins

- Atmel

- Robbins & Myers UK Ltd

- Macdonalds Engineering

- Schlumberger

- Wallace Camerons

- Hydrasun

- Petrofac

- Macmillan Cancer Trust

- Sandvik

- Methode Electronics

- Renfrewshire Council

- Helena Homes

- William Grant & Sons

- Quality Scotland

- Castle Systems

- Mathiesons

- QAS Copak

- Compugraphics

- Smith Anderson

- A.A.M.

- John McGavigan Ltd

- Bon Accord Care

- NHS

- Central Pharma

- United Closures UCP

- Mathiesons

- BAE Systems

- North British Distillery

- Sense Scotland

- Loch Fyne Oysters

- API Foils

- Raytheon

- Kelvin Hughes

- Metalysis

- Vernacare

- Macphie of Glenbervie

- Global Energy (Inverness)

- Land Energy (Girvin)

- Cascade Technologies

- Scottish Leather Group

- Silberline

- Caledonian Produce

- SIMs

- Albion Automotive

- Optos

- Capita

- Johnstons of Elgin

- Glasgow Caledonian University

- MESL

- Oceaneering

- University of St Andrews

- Tepnel Hologic

- Synergie

- Robbins & Myers UK Ltd

- GA Engineering

- Packard Bell

- BioReliance

- Lifetech – Invitrogen